Researchers at the Princeton Plasma Physics Laboratory have devised an innovative way to protect fusion reactors from the intense heat of plasma using a liquid metal evaporator. This breakthrough could pave the way for commercial fusion energy, a clean and limitless power source.

The Power of the Liquid Metal

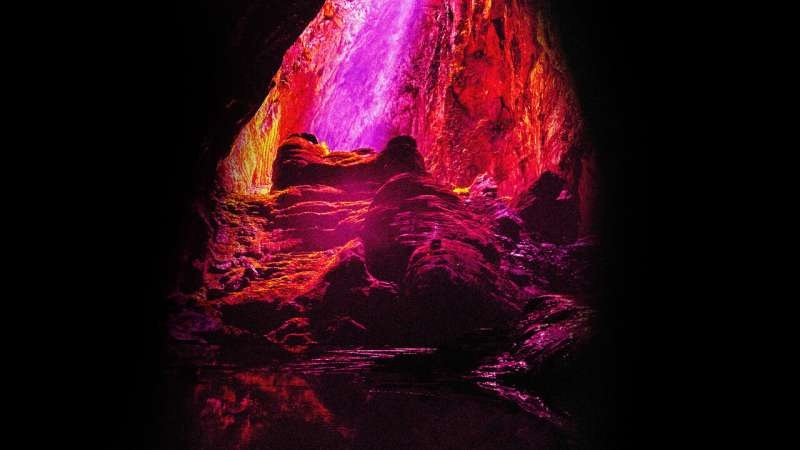

For the next generation of fusion reactors, called spherical tokamaks, scientists have imagined something a bit different: A hot region surrounded by flowing liquid metal — almost like an underground cave. The concept was born from several decades of advanced materials research, through PPPL’s long relationship with the Science and Technology Facilities Council in the UK — a world expert on liquid metals such as liquid lithium.

The trick lies in the evaporator, a heated surface that boils lithium atoms. They intercept the excess heat in the fusion reactor and dissipate it by firing these lithium vapor particles down a path, effectively spreading out the energy so that no one specific point receives intense enough heat to destroy the reactor. Researchers discovered that the best location for the lithium vapor ‘cave’ would be at the bottom of the tokamak, near where there is a central stack, which was where excess heat to accumulate.

Innovative design thinking needs simplification

At first, the researchers assumed they would put the lithium in a “metal box” with a hole at one end for the plasma to enter and at the top of it, in order to allow any heat generated by flowing into and cooling off from metal. But they found that a simpler “cave” design produced the same result in numerous computer simulations.

The walls at the top, bottom and outer sidewall are assigned a ‘cave’ configuration where there is no impermeable surface–thereby providing an optimally long path for lithium evaporating from the walls–and directs LR directionally to improve heat retrieval in PFR. This not only simplifies the device but also improved heat dissipation efficiency.

A second technique suggested by the PPPL researchers: a porous, plasma-facing wall that would let liquid lithium run rapidly beneath. Easily adaptable to a standard, near-term tokamak wall shape with an extension at its outer edge or ‘scrape off layer’, the CAP system uses the shallow angle magnetic field of a fusion device to steer lithium capillary systems towards specific plasma facing components in the divertor region where they will provide external lithium. This high-tech remedy is an inherently simpler-by one measure, albeit a pretty important one-than the lithium vapor cave as a way to draw off the almost unimaginable heat within the heart of the fusion plasma.

Conclusion

Research at the Princeton Plasma Physics Laboratory has brought the possibility of practical fusion energy a considerable step closer. Thanks to the power of liquid metal evaporation combined with novel design strategies, researchers have discovered a way to shield fusion reactors from the heat created by the plasma – one of the key challenges on our quest for clean, abundant energy. As they test and refine these ideas further, the likelihood of fusion power joining the world’s energy grid in a reliable and sustainable manner is that step closer.