Explore the groundbreaking research that reveals the complex interplay between fluid dynamics and the vibrational properties of conical shells, reshaping the future of aerospace, marine, and civil engineering.

Unraveling the Conical Enigma

Conical shells are vital structural elements used in a wide range of applications from aerospace to marine engineering. Conical structures are relatively unexplored compared to cylindrical shells for which traditional research has focused primarily.

Interfaces are intricately nested within these complex structures with internal fluids and are strong determinants in their stability and performance. One of these areas that stands as a critical challenge in utilizing fluid-filled conical shells for a broad range of engineering disciplines is tackled.

To combat this, a group of researchers from the Laboratory of Functional Materials and Institute of Continuous Media Mechanics launched an extensive investigation aimed at gaining full knowledge on the vibrational behavior exhibited by these cone shaped structures filled with fluid. The International Journal of Mechanical System Dynamics has published the groundbreaking research, providing a basis for improvements in engineering design and safety.

Fluid-Structure Symphony Modeling

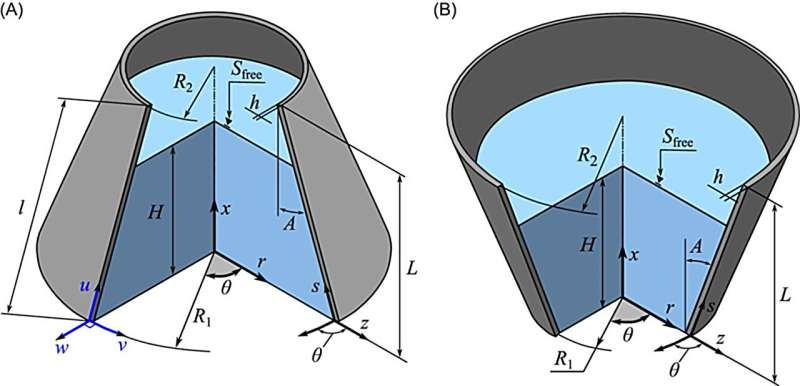

Classical shell theory and acoustic approximations were used by the researchers to study the vibration characteristics of partially filled truncated conical shells with perfect compressible fluid inside. By using a system of ordinary differential equations to model the dynamic behavior of these structures, they were able to utilize both the generalized differential quadrature and Godunov’s orthogonal sweep methods to find the complex interplay among fluid levels, cone angles, natural frequencies with respect to shell mass densities.

These boundary conditions included: simply supported, rigidly clamped, cantilevered etc., so that a complete carnal vibrational analysis could be carried out. Based on the numerical analyses, it was found some configurations can present higher natural frequencies when compared to their cylindrical version, which provides interesting information for further design and application of conical shells filled with fluid.

To demonstrate the accuracy and reliability of their results, the researchers verified them in detail for known numerical and analytical solutions. By doing this, we establish a solid validation routewise to guide the manifestation of these insights using engineering design and decision-making.

Conclusion

This groundbreaking research has a wide range of applications, especially for industries — such as nuclear power plants or mines — which rely on fluid-filled conical shells to perform correctly. The information could inform better design and optimization strategies to enhance top performance and safety in contexts ranging from aerospace to civil engineering. With further developments in future studies, potentially with the addition of real-world conditions, a deeper analysis of fluid-structure interactions may lead to significant advances in engineering practice and safety.