Researchers at Chulalongkorn University have developed a novel extraction method using liquefied dimethyl ether (LDME) to produce high-quality rice bran oil, addressing the environmental concerns associated with traditional hexane-based extraction. This breakthrough technology offers a more sustainable and efficient alternative, paving the way for a greener future in the global demand for high-value oils. Rice bran oil and dimethyl ether are the key focus areas of this innovative study.

Harnessing the Power of Liquefied Dimethyl Ether

The Kokum plant is extensively important for extracting the oil of kokum which are very high-quality oil also rice bran oil recently become more popular due to its being rich in γ-oryzanol content, its demand creates a global market. Nevertheless, conventional hexane extraction presents environmental risks regarding toxicity and the negative environmental impact of this solvent.

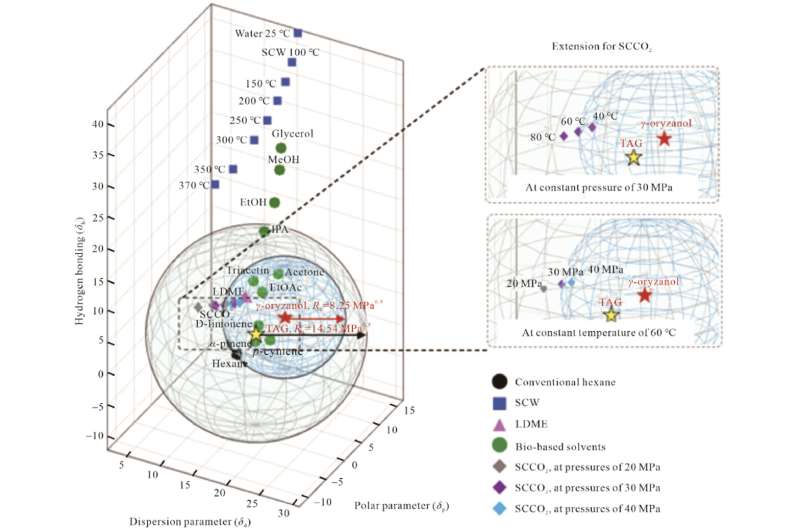

To overcome this difficulty, scientists from Chulalongkorn University are using liquid dimethyl ether (LDME) as a solvent for extraction instead. The research not only characterized the solubility, and oil recovery of LDME when compared to hexane in a previous investigation; however, most importantly it measured the quality of extracted oil quantitatively for the first time. It took few solvents, less time, and lower pressure than hexane to extract similar yields in LDME methods as showed by other researchers.

Unlocking the Sustainability Potential of Rice Bran Oil

Lead author of the study, Phannipha Daisuk, said that these findings were significant in their contribution towards a safer and more environmentally friendly substitution for hexane in the extraction of rice bran oil. The experimental results of this research showed that no negative changes occur in the protein and carbohydrate structures under mildly acidic conditions, thus enhancing the sustainability of rice bran protein by-products.

The study also finalized the use of LDME solvent after its comparison with another prospective alternative, supercritical carbon dioxide (SCCO2). Although SCCO2 was novel in its capabilities, it needed higher solvent-to-rice bran ratios and the inclusion of additional co-solvents to reach equivalent rates of extraction but at a significantly higher cost compared to LDME.

Paving the Way for a Greener Future in Oil Extraction

The results of this study mark an important milestone towards the sustainable utilization of rice bran oil extraction and hence LDME is envisaged to replace hexane in a leading position. Further research must now be done to scale up the process and perform a full techno-economic and life-cycle analysis.

The newly developed extraction process employing LDME not only overcomes the environmental shortcomings posed by conventional methods but also can create new categories of global, high-quality, and sustainable oils that may significantly exceed the capabilities currently possible. Research such as this will be instrumental as the world continues to look for an increasingly lighter impact on the environment and more efficient extraction techniques for consumers.