Entrepreneurship in the field of bioproduction presents both opportunities and challenges. A recent study conducted by a team of students sheds light on the complexities of spider silk production, revealing the need for innovative solutions. The study, published in ACS Biomaterials and Engineering, explores the potential and feasibility of spider silk bioproduction. Discover the fascinating world of biomaterials and the journey toward scalable production in this insightful blog post.

In the universe of bioproduction – civilized organisms as mini-factories – spider silk is in a class all by itself. Spider silk, with its famed strength, flexibility, and versatility, has long been a source of interest from scientists to entrepreneurs. But will be able to rely on nature for its production on an industrial scale?

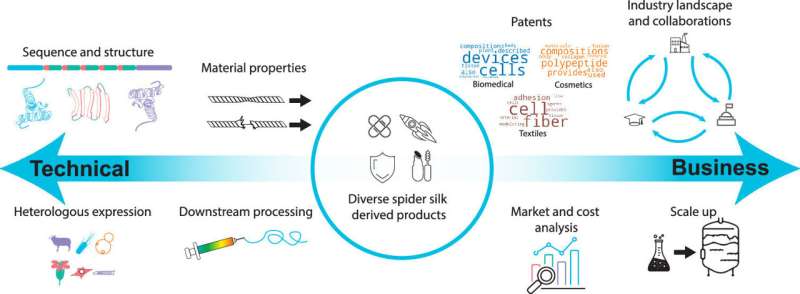

Bioproduction – the use of living organisms for manufacturing provides sustainable alternatives to classical processes. At the forefront of this biotechnological revolution is spider silk whose applications range from high-performance materials to luxury fashion. But scaling up production is still no easy task.

With spiders, which produce the stuff naturally, being territorial and prone to cannibalism, scaling up has proved difficult. Scientists are working to tackle this challenge using new, creative ideas. For example, one method is to genetically engineer other organisms such as bacteria, yeast, or even goats so that they can produce silk proteins.

However, these methods come with their burdens. A study has shown that balancing quality with price is key when deciding which host organisms to use for silk manufacture. The idea is to identify an organism that can produce silk proteins at high levels and as cheaply as possible.

Spider silk is a promising material in many ways. High-tech sensing and measurement equipment could transform bulletproof vests. The fashion industry wants it to produce tough, ultralight, and biodegradable fabrics. Yes, cosmetics industries are seeking its potential in the skincare products.

However, scalability is still a big challenge. Lab-scale production is feasible but upscaling to industrial demands is difficult. This needs perfecting production processes, maintaining quality consistency, and keeping the costs within a limit.

Also, market dynamics are an important factor. Spider silk would need to prove its utility about the available current options, outperforming them in quality as well as benchmark price.

Spider silk held advance has myriad issues to overcome, but the future of spider silk is bright. With spider silk now leaping from an exotic novelty to a practical technology, these companies stand in good stead to capitalize. You gotta have at least a basic scientific understanding, you also better have some business acumen and, oh yes, patience will pay dividends for those still standing when the dust settles.

However, if research continues as well as it has been, we could be on the verge of a new age in materials science in which the remarkable properties of spider silk are woven into our everyday existence with ease. Spinning the future from spider silk