As the world’s energy needs continue to grow, the oil and gas industry is increasingly turning to deep, hard rock formations to meet demand. This shift poses a significant challenge, as traditional polycrystalline diamond compact (PDC) drill bits often struggle to efficiently break through these tough rock layers. In a recent study, researchers from the China University of Petroleum developed a new approach to optimize PDC cutter performance, balancing drilling efficiency and cutter stability. By analyzing the rock-breaking mechanisms and cutting force dynamics of various PDC cutter shapes, the team was able to identify the optimal cutting depths and angles for three common cutter designs – planar, stinger, and machete. This breakthrough could lead to significant improvements in deep drilling operations, reducing costs and boosting productivity. Petroleum engineering and drilling engineering may never be the same.

Optimizing PDC Cutter Performance

To address this challenge, researchers from the China University of Petroleum recently conducted a comprehensive study to better understand the rock-breaking mechanisms of different PDC cutter designs and identify the optimal cutting parameters for maximizing drilling efficiency.

The Key: Balancing Stability and Efficiency

The researchers found that the performance of PDC cutters is largely determined by two crucial factors: stability and efficiency. Stability refers to the consistency of the cutting forces experienced by the cutter, while efficiency relates to the energy required to break a unit volume of rock.

Ideally, PDC cutters should maintain a stable, consistent cutting force to minimize wear and damage, while also minimizing the overall energy consumption of the drilling process. However, these two factors can often be at odds, as the conditions that maximize efficiency (e.g., deeper cutting depths) can also lead to greater force fluctuations and reduced stability.

Analyzing Different Cutter Designs

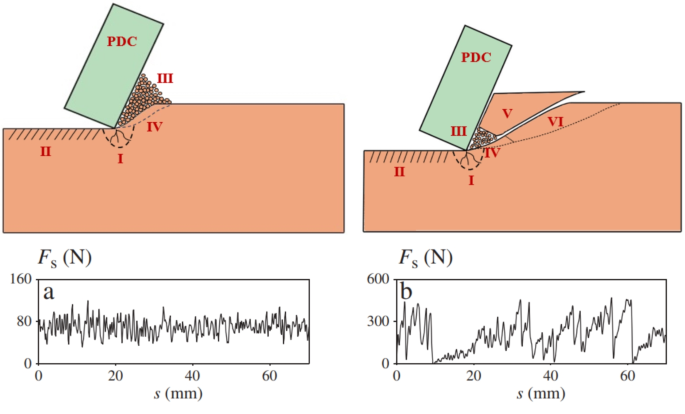

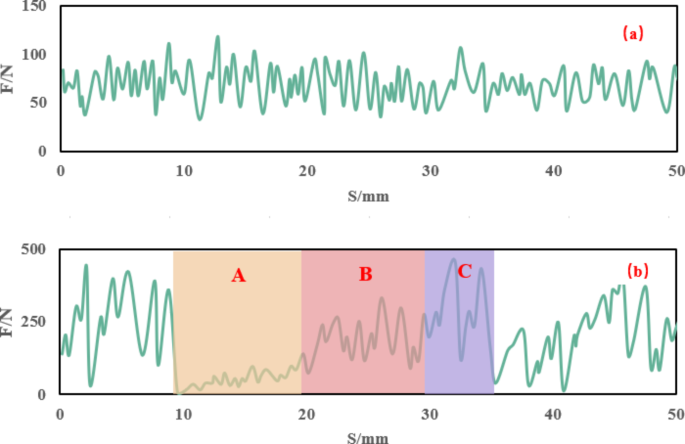

To find the optimal balance, the researchers used advanced finite-discrete element method (FDEM) simulations to study the rock-breaking performance of three common PDC cutter designs: planar, stinger, and machete.

By analyzing the cutting force patterns and rock fragmentation characteristics of each cutter, the team was able to develop a new Stability Index (SI) metric, which quantifies the proportion of energy consumed during the stable versus fluctuating stages of the cutting process. They then combined this SI metric with the traditional Mechanical Specific Energy (MSE) measure to evaluate the overall performance of the different cutter designs.

Fig. 2

Identifying Optimal Cutting Parameters

The results of the simulations revealed some key insights:

– Planar Cutters: Perform best at a cutting depth of 1.5 mm and an angle less than 20°, offering stable performance with relatively high cutting force requirements.

– Stinger Cutters: Perform optimally at a cutting depth of 2 mm and an angle of 20°, requiring lower cutting forces but exhibiting more fluctuations.

– Machete Cutters: Exhibit a balance of planar and stinger characteristics, performing well at a depth of 2 mm and an angle less than 10°.

By carefully considering both the SI and MSE metrics, the researchers were able to determine the cutting parameters that provide the best compromise between drilling efficiency and cutter stability for each design.

Implications for the Oil and Gas Industry

This breakthrough research could have significant implications for the oil and gas industry, enabling drilling operators to optimize their PDC bit selection and cutting parameters to boost productivity and reduce costs in deep, hard rock formations.

Key benefits include:

– Improved drilling efficiency, reducing the time and energy required to reach target depths

– Increased cutter lifespan and reduced maintenance, thanks to more stable cutting forces

– Reduced wear and damage to PDC bits, lowering replacement and repair expenses

As the world’s energy demands continue to grow, innovations like these in drilling engineering will be crucial to unlocking the oil and gas resources needed to power our future.

Author Credit: This article is based on research by Xinrui Wang, Hui Zhang, Zhuoxin Dong, Jun Li, Cheng Qin, Boyuan Yang, Yuting Zhou.

For More Related Articles Click Here