The new adhesive, partially inspired by the way mussels affix themselves to rocks in the tide and surf zone, represents a forward-thinking (and sticky) approach to launch society into an era of reusability and economic circularity.

Sustainable Microelectronics

A common problem with many modern integrated microelectronic devices is the ability to repair and recycle. Likewise, these gadgets are usually fabricated with strong adhesives that make them hard to disassemble and reuse.

This is where debondable adhesives come in, emerging as an important facilitator of the shift to a more circular economy. By creating ‘switchable’ adhesives and ‘detachable’ formulations, researchers are laying the groundwork for more sustainable resource utilisation, less waste, and highly selective strategies that could have significant impacts on repair and recycling.

Mussel-Inspired Brilliance

These mussel masters were the inspiration behind this new adhesive technology. Adhesive proteins in mussels allow the marine mollusks to anchor themselves to surfaces despite being buffeted by turbulent waves.

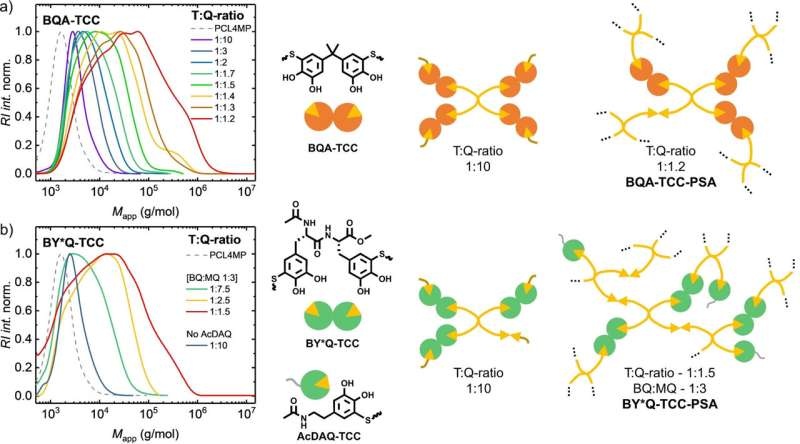

Mussel-inspired adhesives have been developed before but this new method of thiol-catechol polyaddition is an innovation in the field. During this process, the adhesive thiol-catechol connectivity (TCC) in polysulfides polyadduct with other TCC derivatives to form highly adhesive, crosslinked polymers.

The innovation is essentially the oxidation of these catechol groups within the adhesive polymers to quinones (six-membered rings with two oxygens bound by double bonds). This change significantly reduces the bond strength of the adhesive such that it releases easily from a surface.

Conclusion

The creation of this mussel inspired, de-bondable adhesive technology marks an important step towards realizing a circular and more sustainable economy. It could help to reduce waste; conserve resources, and allow for next-generation repair and recycling strategies. While it may still be a ways off, once the researchers have perfected this technology, it could do wonders for everything from consumer electronics to aerospace.