Ensuring the reliability and longevity of complex machinery is crucial for industries like aviation, manufacturing, and energy production. Researchers have developed an advanced algorithm that can more accurately predict the remaining useful life (RUL) of equipment like aircraft engines by combining improved data filtering techniques and a powerful deep learning framework. This innovative approach could lead to better maintenance planning, reduced downtime, and improved safety. The study, published in the journal Scientific Reports, demonstrates the power of integrating data preprocessing and cutting-edge machine learning to tackle challenging real-world problems.

Extending the Lifespan of Complex Machinery

Imagine an aircraft engine, a high-precision industrial robot, or a critical power generation turbine. These complex machines are the backbone of many industries, but their reliable operation is essential for safety, productivity, and cost-effectiveness. When such equipment fails unexpectedly, the consequences can be severe – from expensive repairs to devastating accidents. That’s why accurately predicting the remaining useful life (RUL) of these machines is so important.

Tackling the Challenges of RUL Prediction

Predicting RUL is a notoriously difficult challenge. Complex machinery is subject to a variety of external and internal factors that can cause gradual degradation over time, making it hard to model the deterioration process accurately. Traditional statistical models often fall short, as they require extensive prior knowledge about the equipment and its failure modes.

A Smarter Approach to RUL Prediction

To address these challenges, a team of researchers developed a novel algorithm that combines an improved data filtering technique with a powerful deep learning framework. The key innovations include:

1. Enhanced data preprocessing: The researchers used an improved Savitzky-Golay filter to smooth the sensor data and extract more meaningful features, especially under dynamic operating conditions.

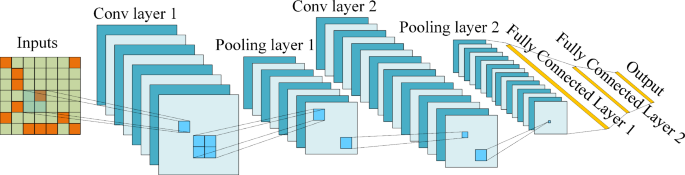

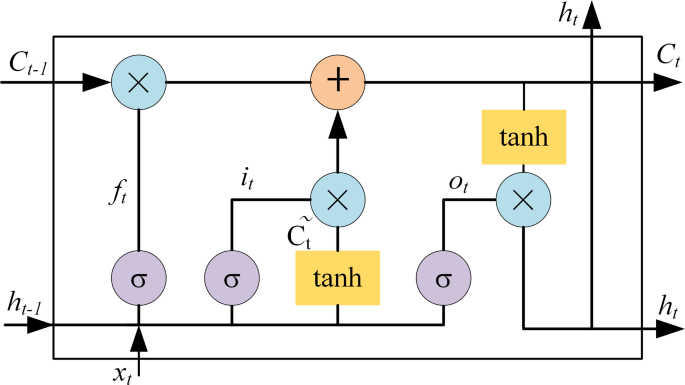

2. Multilayered deep learning: The algorithm uses a multi-channel, multi-scale deep convolutional neural network (MuMsDCNN) integrated with long short-term memory (LSTM) modules. This allows the model to capture both spatial and temporal patterns in the sensor data, improving the accuracy of RUL predictions.

Fig. 2

Validating the Approach on Aircraft Engines

The researchers tested their algorithm on the well-known C-MAPSS dataset, which contains simulated data on the performance degradation of aircraft turbofan engines. Compared to other state-of-the-art methods, the ISG-MuMsDCNN-LSTM approach demonstrated superior performance, particularly in predicting RUL under dynamic operating conditions.

Implications for Industry

The ability to accurately predict the remaining useful life of complex equipment has far-reaching implications. It can enable:

– Improved maintenance planning: By forecasting when a machine is likely to fail, operators can schedule maintenance and repairs more efficiently, reducing downtime and costs.

– Enhanced safety: Accurate RUL predictions can help identify potential failures before they occur, preventing costly and dangerous breakdowns.

– Optimized asset management: With a better understanding of equipment lifespans, businesses can make more informed decisions about investments, replacements, and upgrades.

Advancing the State of the Art

This research represents a significant step forward in the field of prognostics and health management. By seamlessly integrating data preprocessing and deep learning, the researchers have created a versatile and robust algorithm that can tackle the complexities of RUL prediction. As industries continue to demand more reliable and efficient machinery, tools like this will play an increasingly important role in ensuring the longevity and safety of critical equipment.

Author credit: This article is based on research by Xiangyang Li, Lijun Wang, Chengguang Wang, Xiao Ma, Bin Miao, Donglai Xu, Ruixue Cheng.

For More Related Articles Click Here