Physicists at the University of Cambridge have been successful in developing a 3D photonic crystal that completely blocks light across the visible spectrum–the first time a single material has done this at optical wavelengths. It has enormous potential for a variety of industries, from telecommunications to quantum computing.

MASTERING 3D PRINTING OF PHOTONIC CRYSTOLS

Photonic crystals are substances that have complex and ordered inner structures, which also interact with light in some manners that a variety of distinct optical phenomena can be obtained. 1 and 2D photonic crystals have found extensive application in different areas, but the ultimate goal in this field is the development of 3D photonic crystals with a complete visible gap. This has been proved to be an extremely difficult task, and nanoscale control of all three dimensions during the fabrication process needed.

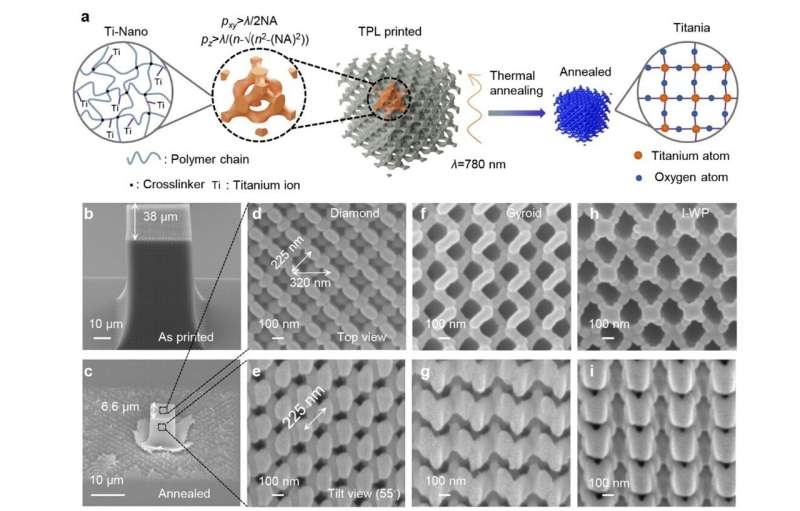

Scientists at Singapore University of Technology and Design (SUTD) — led by Professor Joel Yang — have created a new way to 3D-print these hard-to-create photonic crystals. This new method has finally produced some of the highest resolution, most refractiveness and most complete bandgap crystals ever built across the entire visible spectrum. Researchers said the technology is a major step forward in the field of photonics, promising to vastly improve future applications.

Then there is the titanium dioxide.

The secret to this success has been the material used in all of these 3D printed photonic crystals — titanium dioxide, or titania. Titania is an inorganic material that has a high refractive index which is necessary in order to make a full photonic bandgap to block all the visible radiation.

Before that, the commercially available resins were organic materials with low refractive indexes, all used in two-photon polymerization lithography (TPL) printing, which is also the method that the SUTD team used. Which meant, all printed structures would fail to reach the desired complete photonic bandgap in the visible range.

However, with the help of a new titanium resin and method for heating these 3D-printed structures to convert them into pure titania, the researchers were able to get around this obstacle fine. The 3D photonic crystals it produces are therefore not only high-resolution but exhibit a pitch (the separation between different layers) as small as 180 nanometers post-shrinkage that takes place during the heat-processing of layer formation. This ultra-exact specification is a demonstration of the team’s command over materials science and nanofabrication approaches.

Conclusion

The ability to fabricate photonic crystals within the full bandgap range of the visible spectrum is a groundbreaking accomplishment in 3D printed photonics. The potential uses of this technology are broad — spanning from telecommunications and sensing to quantum information processing. With the use of titanium dioxide and highly sophisticated 3D printing method, this allowed the researchers to explore further unconventional ways for development. In one field-spanning collaborative study, the transformative power of ancient DNA was on full display as edge science and engineering met at a junction.