Scientists have made a groundbreaking discovery by using machine learning to accelerate the development of refractory high-entropy alloys (RHEAs) with exceptional mechanical properties, opening new possibilities for high-temperature applications.

Building Past the Physical

NiSuperalloys, traditional high-temperature materials -have inherent limitations on their performance range. Since then, researchers have been working to find new alloy compositions that can withstand even harsher conditions — higher temperatures and stronger mechanical stresses.

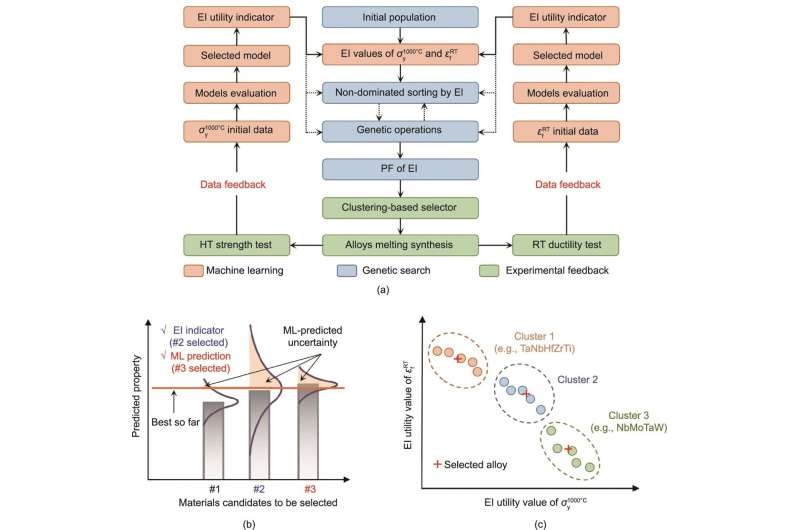

In the realm of refractory high-entropy alloys (RHEAs), the team working under Lookman and Yanjing Su has revealed an innovative method using machine learning (ML) to predict and optimize the composition of superior mechanical properties within metallic materials. After searching through billions of possible combinations, the researchers narrowed down to 24 potential alloy compositions for development and testing, leading them to the identification of four alloys with outstanding high-temperature yield strength and room temperature ductility.

Materials Science Breakthrough

The specific composition Zr0. 13Nb0. 27Mo0. 26Hf0. 13Ta0. 21, turned in an outstanding showing. Thus, the present alloy displayed an appreciable yield strength of close to 940 MPa at 1200 °C which exceeded both the other previously produced RHEAs and also the conventional nickel-based superalloys.

Such a significant improvement in high-temperature strength enables new opportunities for applications of interest high-temperature structural components such as, gas turbines engines; aircraft propulsion systems and nuclear reactors. Described research strategy signifies a whole new concept in materials design, being able to handle the immense compositional space of RHEAs and optimise multiple performance targets simultaneously.

Through a single-click seamless process, the team was able to resolve common issues in alloy design tasks such as sparse data, darkness and unreasonable optimization burdens by integrating machine learning with conventional alloy design.§ The result not only overcomes the shortcomings of current materials, it sets a new benchmark for high-temperature alloys.

Conclusion

The work lays the foundation for future in material design and ancient compositional breadth, a trend that will keep growing with ever more mixed compositions. By incorporating machine learning, the possibility to create high-temperature alloys with extraordinary attributes is opened up and uptake into different engineering applications will also rise as well as an expanded limit of into how materials science can push forwards.