Discover how a groundbreaking technology using magnetic micro spinbots is transforming the world of precision manufacturing, enabling ultra-low surface roughness and contaminant-free surfaces at a fraction of the cost and environmental impact of traditional methods.

Goodbye to Costly Polishing

The semiconductor and optics industries have struggled to obtain extremely low surface roughness and clean surfaces from the manufacturing side. While some of the traditional methods (e.g., chemical-mechanical planarization [CMP] and post-CMP cleaning system) have been widely known to the industry, they all require their own drawbacks.

CMP equipment is large, complex, and prohibitively expensive for cost-effective volume scaling or rapid upgrading. And the consumables (polishing pads, abrasive slurry, and cleaning brushes) for these processes are very expensive and must be replaced often which generates high operational costs. The requirement of high upfront costs and ongoing maintenance for a system has been one of the most significant barriers when it comes to manufacturers looking to lower production costs and improve yield.

Meet the marvel of science — magnetic micro spinbots Created by a group of researchers, led by Professor Sanha Kim at the Korea Advanced Institute of Science and Technology (KAIST), and including Hanyang University Professor Jeong Jae (JJ) Wie, these small robots provide a lightweight alternative for accurate surface polishing and cleaning as well as being scalable to greater sizes.

Microscopic Marvels: The Power of Spinbots

These spinbots are made of a thermoplastic polyurethane–Fe3O4 nanocomposite, and they are employed in combination with a magnetic stirrer to generate a rotating magnetic field. In this configuration, spinbots are able to self-propel or walk and gyrate over surfaces resulting in exceptional nanometer-sized particle removal efficiency of 99.6%, which is significant for its reduced size and complexity compared to traditional systems.

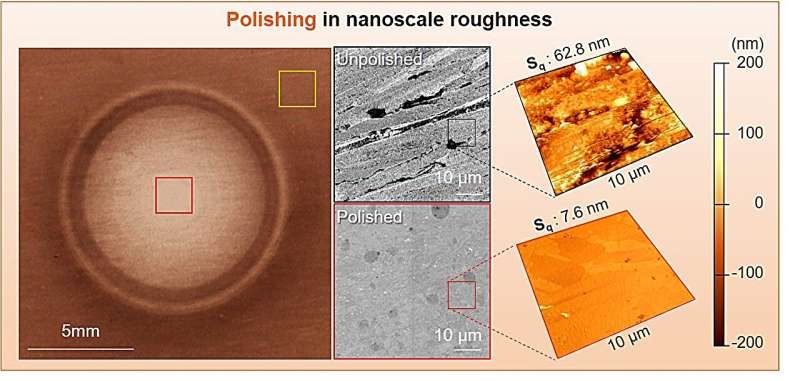

However, the spinbots are good at more than just cleaning. The same smaller scale robots are also able to process surfaces incredibly smoothly, achieving roughness levels as low as 1.8 nm of average roughness (Ra). Their secret to becoming so successful is the performance of three-body abrasion polishing. This traps hard silica particles between the spinbot and ultimately, whatever surface is being polished, milling away at material in a nanometers-scale process. The technique matches or exceeds the smoothest optical fabrication systems available today, including techniques such as ion beam polishing and magnetorheological polishing that are relatively expensive because they require major equipment.

The most powerful differentiator of the technology came from what we had built it on, our SpitBot (scalable platform for internet tokens) architecture. To illustrate this, the set of up to 42 spinbots is mounted on three vertically stacked wafers providing an efficiency level unprecedented in surface engineering. Though tiny in size relative to the spinbot tool is some 1,000 times lighter than typical polishing tools it provides similar or better performance.

Conclusion

The invention of magnetic micro spinbot tech is a big leap for both autonomous and sustainable manufacturing. This offers the ability to revolutionize several industries, from semiconductors and optics, as it provides ultraprecision in polishing & cleaning at a lower cost with hardly any environmental impact. If the research team has their way, the use of spinbot tech in future autonomous production lines would allow precision manufacturing to become more accessible, efficient and sustainable yet.