Discover an innovative method for preparing ionic liquid-based membranes that simplifies the process and enhances mixture separation capabilities. This breakthrough technology has the potential to transform industries ranging from petrochemicals to chemical purification and synthesis, contributing to sustainability efforts. Learn how ionic liquids and membrane technology are converging to unlock new possibilities in mixture separation.

Simplifying the Production of Ionic Liquid-Immobilized Membranes

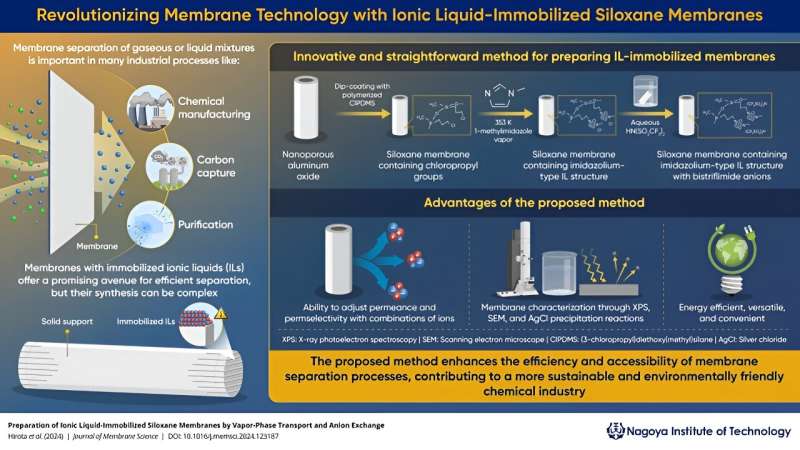

Traditionally, the fabrication of ionic liquid-based membranes for mixture separation has been a complex and time-consuming process. Researchers would first prepare siloxane compounds with an ionic liquid-type group through liquid-phase reactions, and then coat this material onto a nanoporous membrane using a sol-gel technique. This multistep approach was often tedious and lacked flexibility.

To address these challenges, a research team from Japan, led by Associate Professor Yuichiro Hirota from the Nagoya Institute of Technology, has developed a simpler, more versatile, and straightforward method to produce ionic liquid-immobilized membranes. Their innovative solution involves a gas-phase reaction technique called vapor-phase transport (VPT) treatment, which transforms the surface of nanoporous aluminum oxide tubes into an ionic liquid structure.

The VPT Approach: Streamlining Membrane Fabrication

The VPT-based approach begins with dip-coating the nanoporous aluminum oxide tubes in a solution containing polymerized (3-chloropropyl)diethoxy(methyl)silane (ClPDMS). This forms a thin polymeric membrane with exposed chloropropyl groups on the tube’s surface. The researchers then expose these ClPDMS membranes to 1-methylimidazole vapor in a closed vessel, a process known as VPT treatment. This transformation converts nearly all the chloropropyl groups into an imidazolium-type ionic liquid structure, with chlorine anions and imidazolium cations.

The final step involves immersing the membrane-coated tubes in an aqueous HN(SO2CF3)2 solution, which exchanges the chlorine anions for (CF3SO2)2N− anions. This simple, two-step process offers a versatile and efficient way to fabricate ionic liquid-immobilized membranes, overcoming the limitations of the traditional multistep approach.

Evaluating the Performance of the Ionic Liquid-Based Membranes

To validate the effectiveness of the VPT strategy, the research team conducted a thorough characterization of the resulting membranes using various analytical techniques, including X-ray photoelectron spectroscopy, scanning electron microscopy, and AgCl precipitation reactions.

Moreover, they performed permeability and permselectivity tests to evaluate the membranes’ ability to selectively extract different gases, such as H2, H2O, and toluene, from mixtures. The findings of this study demonstrate the excellent potential of the developed techniques for preparing a wide range of ionic liquid-immobilized siloxane membranes, with promising applications in industrial mixture separation processes.

As Hirota states, “Our paper is the first known instance of fabricating separation membranes using VPT and anion exchange in ionic liquid-based materials and evaluating the membranes’ performance in terms of permeation and separation.” This innovative approach paves the way for more accessible and versatile ionic liquid-based membranes, contributing to the advancement of sustainable separation technologies.