In a discovery that points towards the next generation of polymer production, a team of researchers has developed a novel technique capable of tracking the entire lifecycle of even single molecules in real-time thanks to a special form-factor employed known as single-walled carbon nanotubes. The manufacturing sector is approaching a point where the revolutionary nature of this process will completely change our industry, allowing us to become far more efficient and precise in creating products.

Realising the potential of nanomaterials

Single-walled carbon nanotubes (SWNTs) were first discovered about 30 years ago but until now few practical, scalable applications of SWNTs had been identified by researchers; Professor Albert Nasibulin and his group from the Skoltech Photonics†Labroratory of Nano-materials have focused extensively on customized… Such incredible nanomaterials are poised to revolutionize multiple sectors, and the results of this study by the team suggests that it just might.

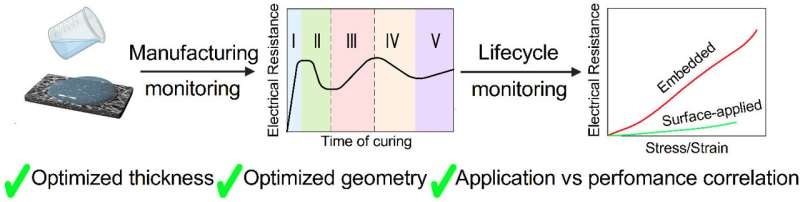

The novel approach relies on sensors made of single-walled carbon nanotubes to measure polymer production variables and test the material when used in practical application Single-sensor monitoring of a polymer allows to track its properties from the moment it is created until its installation and also during the service life.

Challenges in Delivering Sensor Integration

The task of integrating passive sensors into host materials is difficult because the methods usually entail using that material which destroys some of the properties or decreases the sensitivity of a sensor. But the researchers have sidestepped all those challenges, demonstrating how malleable their single-walled carbon nanotube sensors can be.

A co-author, Hassaan Ahmad Butt, research scientist at Laboratory of Nanomaterials in Skoltech Photonics has stated the team had determined the most efficient parameters under which the sensors were working. Through the mere thickness of nanotubes, they are able to adjust the sensitivity and applications of its sensors even enabling them to be incorporated alongside during manufacture of large polymer items without material property loss.

Conclusion

This study provides a proof-of-concept of some ground-breaking work in polymer production. Tapping the potential of the single walled carbon nanotube, the researchers have come up with a simple yet effective method to trace everything that happens in a polymer’s life cycle, from its manufacture all through its journey to the application. This innovation is expected to transform the sector by providing production with increased efficiency, accuracy and more cost-effective methods of manufacturing. While the team has begun working with international partners and is expanding their research, they believe it’s full speed ahead for the future of polymer manufacturing.