Discover a groundbreaking new technique for creating ionic liquid-based membranes that can efficiently separate mixtures, enabling the recovery and reuse of valuable substances while mitigating environmental impact. This innovation holds the potential to transform industries, from petrochemicals to chemical purification, and contribute to the global goal of achieving carbon neutrality. Ionic liquids and membrane separation technology are the keys to this sustainable future.

Unlocking the capabilities of ionic liquid membranes

Mixture separation to individual components can be a crucial application in many industries including petrochemical and chemical synthesis. Additionally, this venture is incredibly sustainable as it facilitates the recycling and repurposing of precious materials, while capturing dangerous gases in an eco-conscious way.

Ionic liquids (ILs) have emerged as an attractive alternative by materials scientist for membrane facilitated mixture separation since they exhibit bespoke and exciting nature. Now, researchers have found a new way to extract these gases from mixtures using ILs immobilized onto porous membranes with the right combination of attractive forces that can be tuned to make them highly selective for one gas over another. This innovative strategy has the tremendous potential of changing the face of industry and leading us toward a sustainable future.

How to Simplify the Route of Ionic Liquid-Membranes

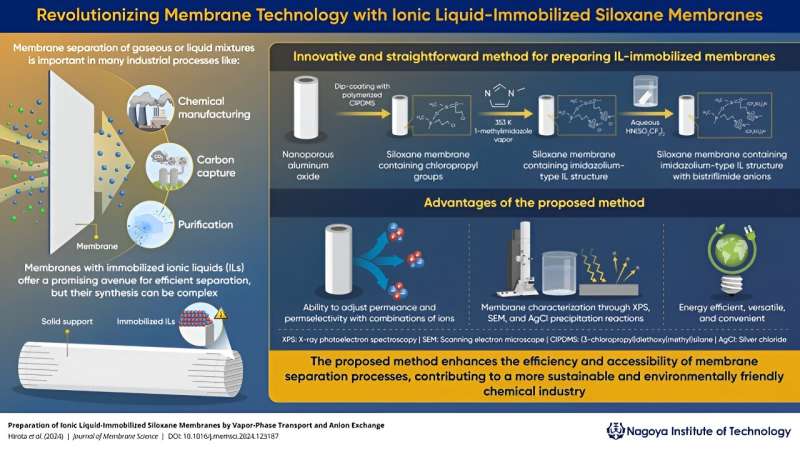

However, the preparation of the IL-containing membranes for dealing with mixtures remains complex and time-consuming. Prior studies have taken a two-step approach to make siloxanes that contain an IL-type group: they made these compounds by liquid-phase reactions and then used the sol-gel method to coat this material onto a nanoporous membrane.

To tackle these problems and lower the barriers to entry for IL-based membranes, a Japan-based research team led by Associate Professor Yuichiro Hirota from the Nagoya Institute of Technology created an easier, more flexible way that was less complicated at its heart. Their innovation lies in two methods: they first immobilize ILs onto the membrane surface using a vapor-phase transport (VPT) method and secondly functionalize polymer with anion exchange groups to prepare high-performance membranes.

Introducing the Novel VPT Method for Ionic Liquid Containing Membranes.

Their method is quick and straightforward: they dip-coat closed-end nanoporous alumina tubes with a solution of polymerized (3-chloropropyl)diethoxy(methyl)silane (ClPDMS), which acts as a structural anchoring agent. This in turn produces a polymer electrolyte, which is made with the nanopores of the tubes open on their backsides to allow chloropropyl groups to hang down from the polymeric material.

The team then uses the VPT technique in which the ClPDMS membrane is introduced into a sealed vessel and heated up to a controlled temperature at 1-methylimidazole exposure. With more chloropropyl groups inside, almost all of them are replaced by the cations after this conversion leading to an imidazolium-type IL with chlorine anions and imidazolim cations. Lastly, the researchers put the tubes with membrane coated in an aqueous solution of HN(SO2CF3)2 thus changing the anion from Cl− to (CF3SO2)2N−.

This unique process not only enables ease of fabrication but also versatility in preparing membranes tailored for various mixture separation applications. The membranes were systematically characterized by the researchers, and permeability and permselectivity tests proved that the VPT strategy had potential for extracting different gases including H2, H2O, toluene from mixtures.