Explore the groundbreaking research at North Carolina State University on using non-wood cellulose feedstocks to produce sustainable man-made cellulosic fibers (MMCFs) for the textile industry. Discover how this innovative approach could tackle the environmental challenges posed by synthetic fibers like polyester and provide a more eco-friendly alternative. Textile industry and sustainability are key focuses.

Unlocking non-wood feedstocks potential

The textile industry today stands at a crossroad, facing serious issues on two fronts: Environmental Awareness & Shift to Sustainability. Non-wood cellulose-based textiles could provide a solution according to new research from North Carolina State University

Published in the Journal of Bioresources and Bioproducts, the study looks into the suitability and promise of new non-wood feedstocks for producing man-made cellulosic fibers (MMCFs), which has largely been an area ruled by wood-derived pulp. Headed by lead author Ryen M. Frazier and postdoctoral associate Ronalds Gonzalez, the research paper builds a strong argument for alternatives to current biobased materials used in the plastics industry.

The Environmental Cost of Synthetic Fibres

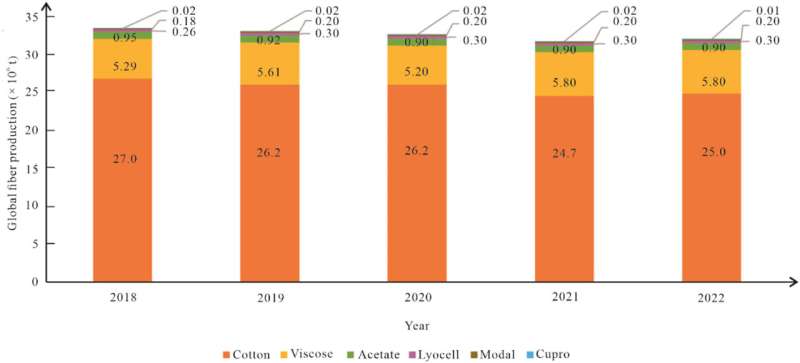

The report is published at a time when the textile industry is struggling with treatment of environmental issues from the use of synthetic polyester fibers that already has over 50 percent market share in fashion. This is because global textile production has increased, increasing the reliance on resources and environmental impact.

Findings indicate that agro-residue raw materials and dedicated fiber crops have the potential to serve as economic substitutes for wood-based pulps. The resulting roadmap to incorporate these feedstocks into MMCF production will help the industry navigate toward a greener future, less dependent on resource-intensive and environmentally-taxing synthetic alternatives.

Sustainable Fiber Production Solutions

The drive to non-wood cellulose fibers is not only a matter of sustainability, it’s also about new innovations. The different conversion technologies appropriate for the provision of textile-grade fibers from dissolving pulps based on non-wood without cellulose reddening, together with the details of derivatization and dissolution methods, spinning methods and parameters therein.

A so-called ‘upcoming’ method is tested in the study by spinning fibers from a hydrogel based on undissolved nano/micro-fiber suspension, which was particularly exiting for us. Combining technology with this new concept has the possibility to change the industry, offering a way to produce textiles more sustainability and efficiently. The researchers conclude that while there are still challenges, such as impurities in the raw material, and Northern Hemisphere-focused equipment unable to cater for Southern Hemisphered non-wood feedstocks, the future of sustainable MMCF production by integrating non-wood into its basket might hold promise and could not only release pressure on the environment but also bring new avenues for both farmers as well as industries.