Researchers at the University of Hawaiʻi have developed a groundbreaking new technique that could make the production of wearable health sensors more accessible and cost-effective, potentially transforming the future of personalized medical care.

Fabricating Overhead

However, conventional methods of fabricating wearable sensors often need accessibility to specialized facilities and knowledge that remain beyond reach from much wider usage.

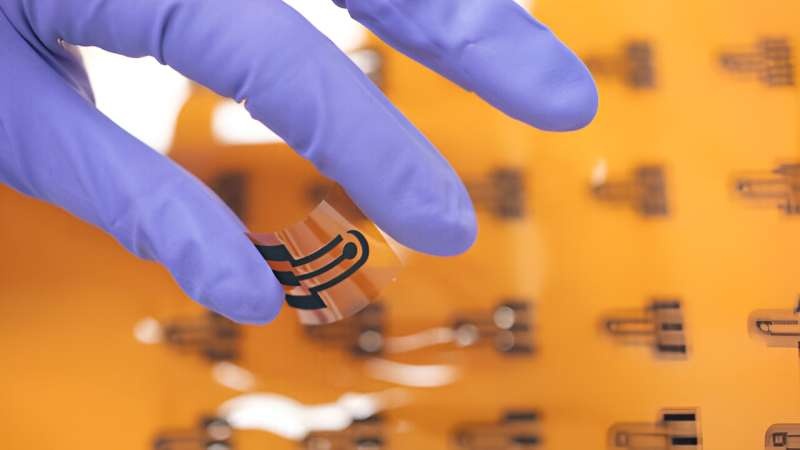

What the University of Hawaiʻi team has is a new and vastly cheaper solution: a stencil-based approach to creating laser-induced graphene (LIG) sensors.

Using off-the-shelf metal stencils let the researchers cut the minimum feature size in half, from 120 micrometers to just 45 micrometers for the sensors. This advancement opens the possibilities for more intricate sensor designs, such as fine-line micro-array electrodes; design elements that are difficult to achieve with conventional laser processing.

Empower Sensors with Better Performance and Improved Functionality

They then put this new method to use by creating temperature sensors and multi-electrode electrochemical sensors, both of which outperformed the standard equivalents.

It is also able to boost further efficiency when producing advanced wearable sensors with enhanced performance and more economically than previous ways of printing, according to the lead researcher on the project Tyler Ray, assistant professor. We have refined the sensitivity and selectivity in our sensors, not only by utilizing an innovative transduction method but also by using a metal stencil processing technique that alleviates some of the main limitations of conventional fabrication—paving the way for unique sensor designs and functionalities.

This was reportedly achieved by more accurately defining the graphene patterns using the stencil-based approach, which resulted in improved resolution and quality of the graphene patterns that contributed to better sensor performance. The discovery could lead to the creation of advanced, flexible, and personalized wearable health monitoring systems that are economical and can be made available to a broader population.

Conclusion

This stencil-based approach created by the University of Hawaiʻi researchers can be a game-changer in the way future wearable health sensors are made. Breaking through traditional barriers of fabrication, this advance could enable the development of high-performance personal health-monitoring devices that are cost-effective and more accessible to a wider population, supporting the prospect of personalized preventive medicine. The impact of this breakthrough innovation goes beyond the laboratory, hopefully paving the way to a new practice in healthcare and a better life for people globally.