Researchers have achieved a groundbreaking feat in the field of photonics by developing a revolutionary method to print 3D photonic crystals that completely block light across the visible spectrum. This innovation holds immense potential for transforming industries and advancing various technologies.

Unlocking the Secret of 3D Photonic Crystals

Photonic crystals are materials that consist of periodically arranged internal structures whose excellent interaction with light allows the creation of many new photonic devices. Although 1D and 2D photonic crystals have been widely applied as novel materials, it remains a huge challenge to design the 3D perfect PC in visible range.

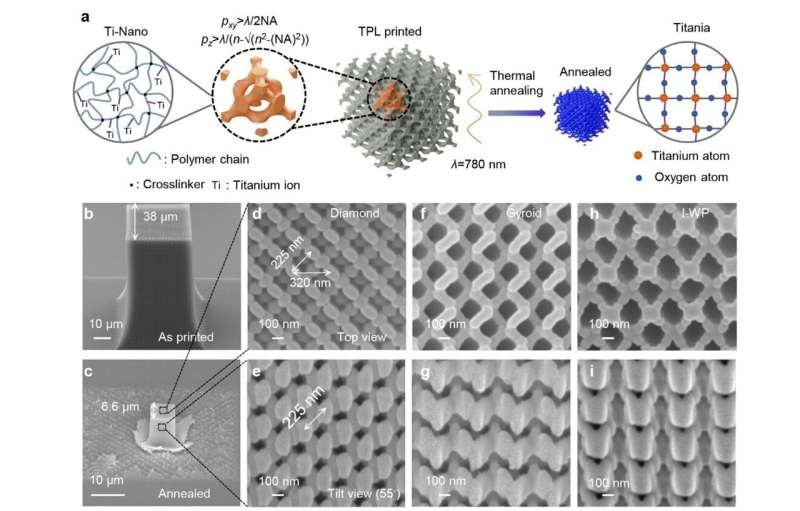

The reason this has been a challenge, is that all three dimensions needed to be manipulated in near-nanoscale control during the fabrication process. But researchers from the Singapore University of Technology and Design (SUTD) in collaboration with China-based institutions have developed an innovative technique to 3D print photonic crystals using a specialty titanium resin.

This new method also makes it the first to produce high-resolution, high-refractive-index, visible-range 3D photonic crystals with a complete bandgap. It is a major advance in the field of photonics, and shapes the way for many different sectors and applications.

Harnessing the Power of Titanium Dioxide

The secret of the researchers’ success is in the use of an inorganic material: titanium dioxide (titania) has a very high refractive index. For commercially available resins in the two-photon polymerization lithography (TPL) technique, which is used for additive manufacturing, organic materials with low refractive index are most often applied. So ergo, it would have been pretty much impossible for any printed object to fully block the entire visible light spectrum.

The team was able to leverage the optical properties of titania by creating a proprietary titanium resin. Titania is already in use elsewhere, bookmarking its white properties due to light scattering and abundance of common goods such as toothpaste, sunscreen, and self-cleaning surfaces.

When making the photonic crystals, after these have been printed with TPL and cooled down again, heating them in air causes the evaporation of all organic and some parts become partially oxidized to transform titanium ions into TiO(2) oxide so that their processed three-dimensional structures show a full three-dimensional band gap for all visible colors.

Conclusion

This work is a major advance for the field of photonics, demonstrating for the first time that it is possible to print a complete photonic bandgap using titanium resin at visible wavelengths. This breakthrough has enormous potential to revolutionize industries by enabling breakthroughs in telecommunications, sensing, quantum technologies and more. This opens up a range of future research as well as future applications in nanoscale fabrication utilizing materials such as glass, ceramics, and metals.