Researchers at Monash University have developed a groundbreaking method to produce sustainable single-atom catalysts (SACs) using biomass-derived materials. These novel catalysts promise to revolutionize the chemical industry by increasing efficiency, reducing waste, and aligning with the principles of green chemistry. This innovative approach opens new possibilities in material design and contributes to the circular biomass economy.

Biogenic Single-Atom Catalysts for Biomass Utilization

The search for sustainable and renewable fuel sources has transitioned from the laboratory to commercial reality. A new study will help accelerate this transition by allowing researchers and companies to accurately measure properties of these fuels, such as their key ingredients and toxins, using advances in chemical analysis. In their paper, A review of solar assisted conversion processes in the chemical industry published in the Journal of Bioresources and Bioproducts, Adrian Chun Minh Loy (Pictured left) and Sankar Bhattacharya (Pictured right) & argue that this new way to produce chemicals has been overlooked for too long.

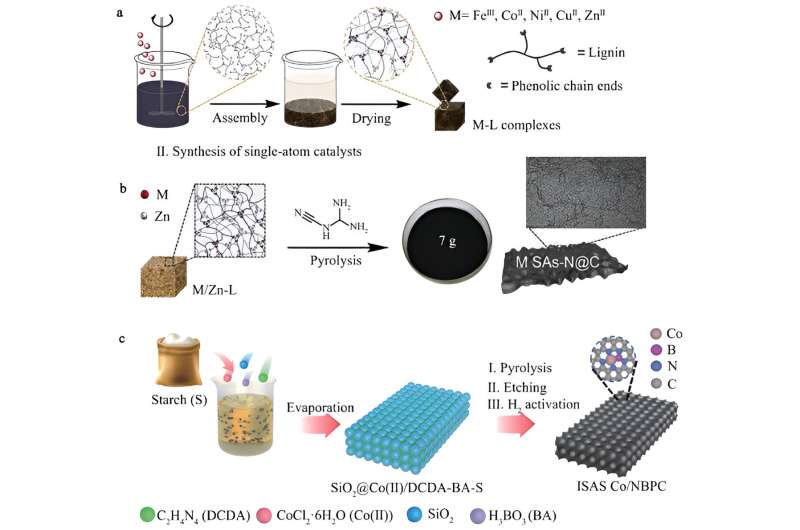

The single-atom catalyst has been considered as a frontier field in material science, because it exhibits several unique properties such as 100% atomic utilization efficiency, maximum selectivity and special electronic structures (e.g., an unsaturated number of the free coordination unsaturated sites). This feature imparts SACs high-efficiency in catalytic conversion with minor waste and then refers to the concept of green chemistry for potential advances. The researchers acknowledge that the high cost of downsizing metal particles for use in sub-angstrom sizes is a major impediment to the widespread production of large-scale SACs. However, the ligands are very inexpensive and derived from biomass.

Utilising Biomass Waste to Achieve Sustainable SAC Production

The original article is aimed to exploit some biomass wastes, such as algae [11], rice husk [12] or metal oxides (MOs) furthest for precursors of SAC production. These results indicate that SACs prepared from biomass are…Views: 62. For example, Zn SACs anchored on lignin exhibit excellent performance in the C-N oxidation cleavage reaction with highly selective aniline production as a result.

As challenging as it is to create biomass-derived SACs, the cost and environmental advantages can be incredibly rewarding for doing so much. The researchers are now calling for additional research to overcome the hurdles in production and catalytic process monitoring in large scale. The Monash University research is ground-breaking for material design and allows new options in the circular biomass economy.

A Greener Chemical Future with SACs Prepared from Biomass

As the globe moves towards sustainability, these SACs produced from biomass may potentially be a key platform for future chemical production. The unique catalysts have the ability to dramatically alter the landscape of catalysis by reducing inefficiencies, waste, and adhering to principles of green chemistry.

Research conducted at Monash University is a large initial step towards this goal and shows that our biomass-derived materials possess extreme potential. The researchers have removed the obstacles to mass-scale SAC fabrication, and it opens a possibility of an even more efficient use of precious metals for chemical production.

Innovative alternatives such as SACs derived from biomass will shape the future of the chemical industry. There is no question that the world will need to shift towards more sustainable practices, but this research provides a ray of hope and a steer for heading toward greener, efficient chemicals future.