Researchers at Cornell University have developed a groundbreaking technique that transforms discarded textiles into eco-friendly, waterproof coatings. This innovative process not only reduces waste but also offers a safer alternative to traditional chemical-laden coatings. With the average American discarding up to 100 pounds of clothing annually, this breakthrough could have a significant impact on reducing the environmental burden of textile waste. Textile industry and waste management are two crucial areas where this research could make a lasting difference.

Upcycling Textile Waste To Create Waterproof Wonders

In a public display of their creative prowess, scientists at Cornell University have engineered an unprecedented low-temperature method that uses waste textiles to manufacture a top-class water-repellent coating. Now, a team led by Juan Hinestroza, the Rebecca Q Morgan ’60 Professor of Fiber Science and Apparel Design, has developed a less environmentally taxed method in which household fabric waste is turned into an all-purpose aerogel by the help of some self- purified nanofibers.

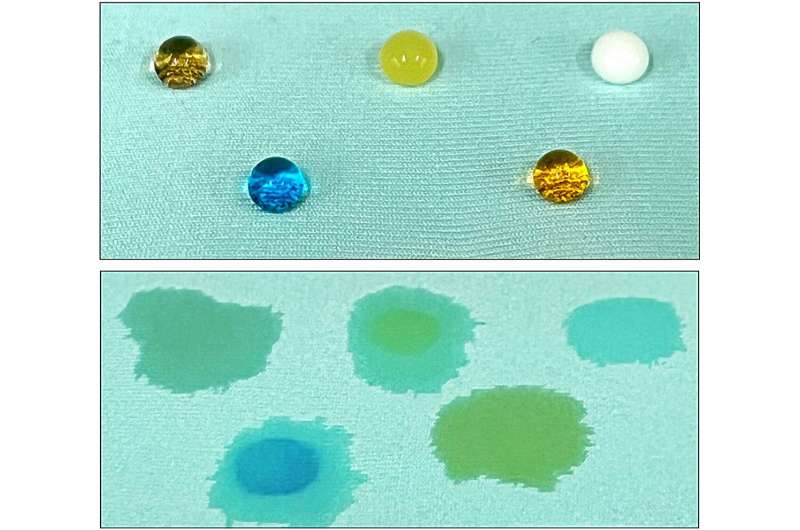

Conventional waterproofing is often made from harsh chemicals and carcinogens, putting human health at risk as well as harming the environment. The new method developed by the Cornell team, on the other hand, provides a greener solution. They were able to chemically decompose used polyester- and spandex-based textiles, producing superhydrophobic (water-repellent) metal-organic structures (MOFs). This both lessens their dependence on harmful chemicals and recycles textiles that would otherwise wind up in the dump.

The power of upcycling: using waste as functional coatings ·

The secret to the teams success goes deeper than front end gimmicks and focuses more up-cycling. The researchers did not throw away the textiles, they chemically depolymerised the thread of discarded polyester and spandex to harvest these compounds which were then used as building blocks in fabrication of MOF based waterproof coating. Thereby it not only reduces textile waste but also circumvents the high-energy separation and purification processes common in traditional coating production.

These discarded fabrics, he notes in a paper, which is published in ACS Applied Materials and Interfaces, contributed scraps of spandex to the mix that helped change the hydrophilic MOF structure to become hydrophobic—water-repellent. A precious surprise being in upcycling that makes one wonder what else can be gained from apparently waste materials.

The Future Is Sustainable: Removing Dangerous Chemicals From the Equation

Research like this has far reaching implications beyond textiles. Tamer Uyar, associate professor of fiber science in the Department of Human Centered Design notes that this technology could help decrease harmful chemical for various manufacturing processes in an era where there is a growing effort to reduce dependence on these world widely used chemicals including volatile organic compounds (VOC), benzene and phenol.

We need to find substitutes for fluorinated finishes, or “forever chemicals,” Uyar notes. The work by this team at Cornell shows that it’s possible to make functional finishes, including ones with water-repellent and self-cleaning properties, without having to use such chemicals. The researchers have essentially created a new, sustainable material through upcycling textile waste and this research is breaking new ground in the field of sustainable material science.

And as so succinctly put by Juan Hinestroza, “If we can save one piece of clothing from being thrown into a landfill then that is a win. The larger context of the research is probably what makes this sentiment even more relatable — simply because it hints towards a more expansive benefit than just waterproof clothing, but instead aiding a long-standing problem of textile waste in the environment.