In the quest for renewable energy sources and effective waste management, researchers have uncovered an innovative solution – co-pyrolysis. This process involves the thermal decomposition of a mixture of waste materials, such as furniture wood, mixed plastics, and waste tires, to produce valuable biofuels. The findings of this study demonstrate the potential for synergistic interactions between these feedstocks, leading to enhanced liquid fuel yields and improved product characteristics. With the global challenges of fossil fuel depletion, plastic pollution, and environmental degradation, this research provides a promising pathway towards a more sustainable future. Pyrolysis, Plastic pollution, and Renewable energy are key concepts underlying this groundbreaking work.

Addressing the Global Waste Crisis through Innovative Solutions

The modern world faces a daunting challenge: the ever-increasing accumulation of waste, from discarded furniture and plastics to used tires. These materials, if not properly managed, can contribute to environmental degradation and pose a threat to human health. Conventional methods of disposal, such as landfilling and incineration, often fall short in addressing the problem’s root causes. However, the researchers behind this study have identified a transformative solution: co-pyrolysis.

Unlocking the Synergistic Potential of Waste Feedstocks

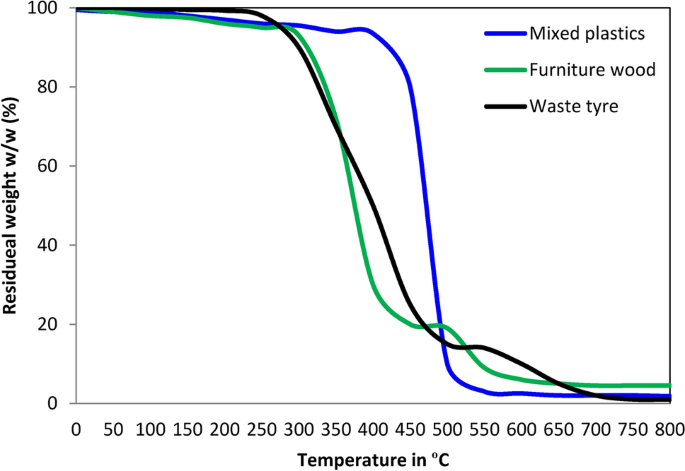

Co-pyrolysis is a process that involves the simultaneous thermal decomposition of multiple waste materials, such as furniture wood, mixed plastics, and waste tires. By carefully blending these feedstocks, the researchers discovered that the resulting interactions can lead to remarkable improvements in biofuel production. The key lies in the complementary properties of the different waste materials.

Maximizing Liquid Fuel Yields through Synergistic Interactions

The study found that the co-pyrolysis of mixed plastics and waste tires yielded the highest amount of liquid biofuel, surpassing the individual pyrolysis of these materials. This remarkable result can be attributed to the synergistic effects between the feedstocks. The high volatile content of the mixed plastics, combined with the thermal stability of the waste tires, created a dynamic process that enhanced the conversion of the materials into valuable liquid fuels.

Unlocking the Chemical Composition of Biofuels

The researchers delved deeper into the chemical characterization of the biofuels produced through co-pyrolysis. Using advanced analytical techniques like chromatography–massspectrometry’>gas chromatography-mass spectrometry (GC-MS), they identified a diverse array of hydrocarbon compounds, including aromatic and aliphatic structures. These findings not only provide insights into the composition of the biofuels but also open up opportunities for their targeted utilization in various industries.

Addressing Environmental Concerns through Sustainable Waste Management

The environmental impact of waste management is a critical concern, and the co-pyrolysis approach offers a promising solution. By converting waste materials into valuable biofuels, the process reduces the burden on landfills and mitigates the harmful emissions associated with traditional disposal methods. Furthermore, the use of these biofuels as alternative energy sources can help offset the reliance on Click Here