Researchers at Monash University have made a groundbreaking discovery in the quest for sustainable chemical production. Their work on biomass-derived single-atom catalysts (SACs) has the potential to transform the industry, offering a cost-effective and environmentally friendly solution. These novel catalysts, composed of biomass waste materials, demonstrate remarkable selectivity and conversion rates, outperforming traditional metal nanoparticle catalysts. As the world moves towards a more sustainable future, this research opens new possibilities for a circular biomass economy.

Unlocking the Power of Biomass

In the pursuit of sustainable chemical production, a team of researchers at Monash University, led by Adrian Chun Minh Loy and Sankar Bhattacharya, have made a groundbreaking discovery. Their study, published in the Journal of Bioresources and Bioproducts, explores the potential of biomass-derived single-atom catalysts (SACs) to revolutionize the chemical industry.

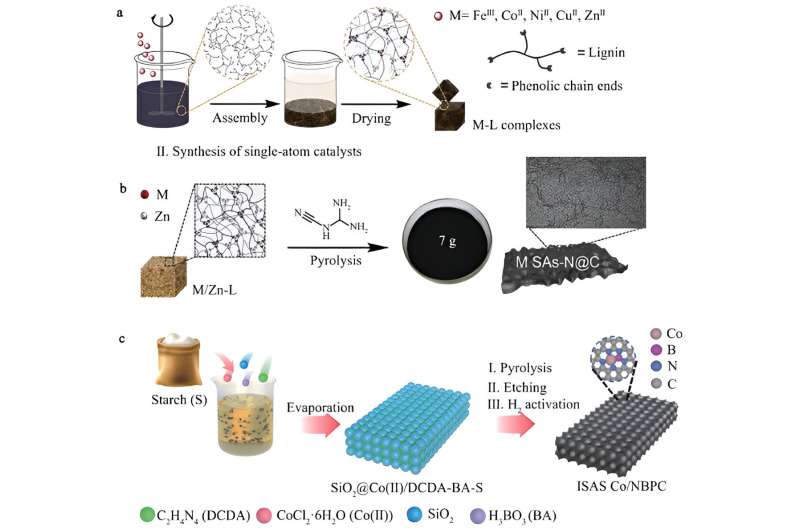

Single-atom catalysts have emerged as a frontier in material science due to their unique properties, such as 100% atomic efficiency, superior selectivity, and distinct electronic structures. These remarkable characteristics enable SACs to perform catalytic reactions with minimal waste and maximum output, perfectly aligning with the principles of green chemistry. The challenge, however, has been the cost-intensive process of reducing metal particles to sub-angstrom dimensions, hindering large-scale fabrication.

Biomass to the Rescue

The Monash University researchers have found a cost-effective and environmentally friendly solution to this challenge: the use of biomass-derived materials as ligands. By utilizing waste from sources such as algae, rice husk, and metal oxides, the team has developed a novel approach to SAC production.

Their findings suggest that biomass-derived SACs can match or even surpass the performance of traditional metal nanoparticle catalysts in terms of selectivity and conversion rates. For instance, lignin-based Zn SACs demonstrated impressive performance in the oxidative cleavage of C-N bonds, achieving high selectivity for aniline production. This breakthrough opens up new possibilities in material design and contributes to the development of a circular biomass economy.

Unlocking a Sustainable Future

While the development of biomass-derived SACs is not without its complexities, the potential benefits in terms of cost savings and environmental sustainability make it a worthy pursuit. The researchers call for further studies to address the challenges of scaling up production and real-time monitoring of catalytic processes.

As the world moves towards more sustainable practices, biomass-derived SACs may become a cornerstone in the future of chemical production. This research from Monash University not only showcases the potential of these innovative catalysts but also highlights the importance of leveraging waste materials to drive a more sustainable future. By transforming biomass into powerful catalysts, we can unlock a new era of green and efficient chemical production, paving the way for a more sustainable and environmentally conscious world.