Learn how scientists are copying the complex patterns found in nature to produce more resilient polymers, leading to technological breakthroughs in materials science.

Bioinspired Breakthrough

The formidable, but surprisingly tough designs found in nature have long-fascinated scientists of biological systems. The sea sponge, for instance. It forms in a complex gradient from bone to softer tissue, creating an ideal mix of hardness and pliability.

Nancy Sottos, a U of I professor of materials science and engineering and a researcher at the Beckman Institute for Advanced Science and Technology who led the study with Frederick Seitz Materials Research Laboratory postdoctoral researcher Wenjie Xia described that this is quite common in nature: “Nature has provided us with an elegant blueprint for strong materials that are both lightweight and tough. Patterned materials generally contain hard and soft areas, enabling them to be stretched a lot without failing while retaining very high strength.

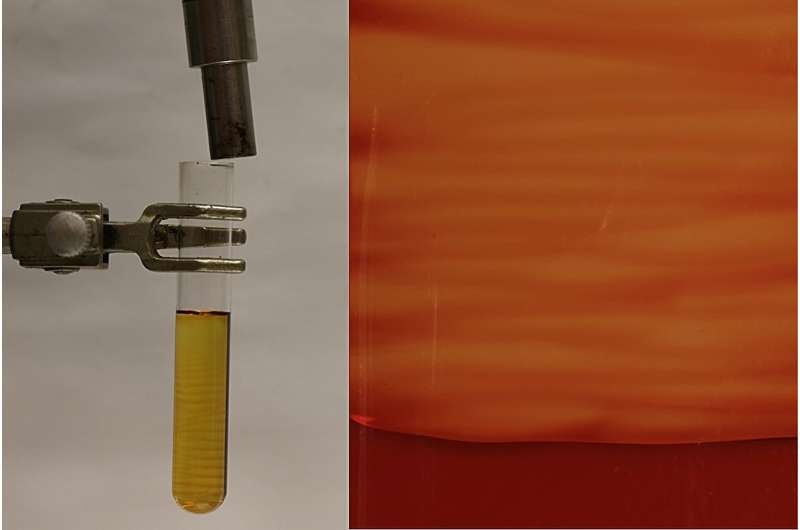

Using a process called frontal polymerization, Researchers led by Nancy Sottos and her interdisciplinary team have discovered how to replicate nature’s method. Here, heat is applied to initiate a chemical reaction forming polymers, which take part in a controlled growth of crystalline patterns within the materials formed. This is an impressive increase in wear resistance, which has the potential to develop new applications across numerous industrial sectors.

Harnessing the Power of Collaboration

The interdisciplinary team at the Beckman Institute is responsible for achieving this groundbreaking result.

The discoveries trace back to work that Beckman researcher and Stanley O. Ikenberry Research Professor Jeff Moore did in fine-tuning the chemical formulations. “This work marks a new frontier — we can now make 3D parts with highly complex shapes but without the need for a mould of any kind, and can produce these parts in materials that are useful,”…

For instance, Cecilia Leal, a professor of materials science and engineering, employed X-ray scattering to see how polymer chains line up in the patterned material—a reminder that researchers must understand everything from molecule to matter in studying structure-property relationships.

Aerospace engineering professor Philippe Geubelle focused on modelling the manufacturing process, to capture the thermo-chemical instabilities that give rise to these heterogeneous materials. “The synergy between experimentalists and modellers on the one hand, of scientists from mechanics to materials science and chemistry on the other, who saw their research integrated across disciplines, was key to the success of this project,” Geubelle said.

This interdisciplinary mindset, which was facilitated by the intellectual open environment of the Beckman Institute, was key in realizing the vision of this biologically-inspired breakthrough in polymer science.

Conclusion

Mimicking nature’s elegant designs would allow for the development of stronger and tougher polymers, a goal long-sought within materials science. Leveraging the spirit of collaboration and incorporating multifaceted views, they have charted paths on hitherto unexplored territories in synthetic materials to transform industry landscape with groundbreaking applications. With the mysteries of nature continuously revealing itself, there is no real limit to where we can innovate and transform.