Scientists from Tokyo Metropolitan University have discovered a novel two-step technique, with which PET can be cleanly extracted from ostensible spreads of textile and plastic waste.

A Game-Changer in Plastic Recycling

On the other end, is a world on plastic waste crisis and we all need to put our foot down. While the rate of recycling of materials, particularly chemical recycling to raw materials, is so far low despite its promotion. Current methods used to break down polyesters, like the kinds that cling wrap and plastic bottles are made of (PET or polyethene terephthalate), usually necessitate high temperatures and rely on large amounts of acidic or basic substances to work which can be costly and damaging to the environment.

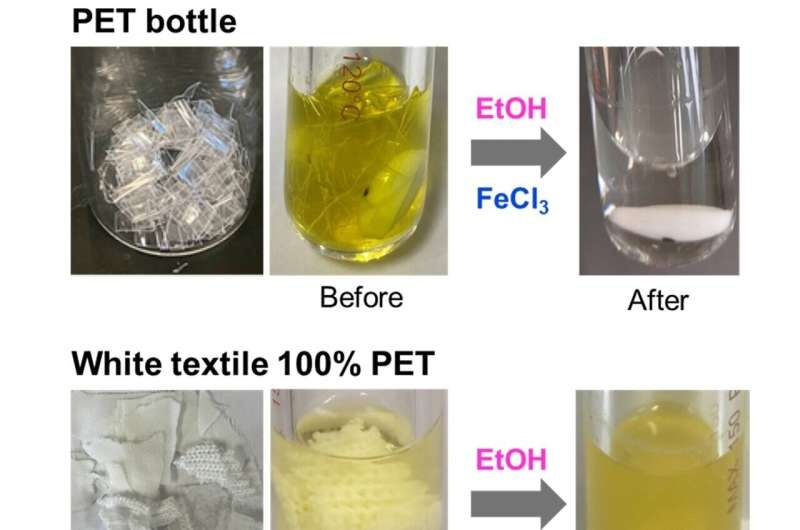

Researchers at Tokyo Metropolitan University led by Kotohiro Nomura developed an innovative solution for this problem. The process involves the selective depolymerization of PET recycling feedstocks by using ethanol as a solvent and an inexpensive, commercially available iron trichloride (FeCl3) catalyst to produce diethyl terephthalate(DET) and ethylene glycol (EG) in high yield (>98-99% selectivity). For example, if this innovative approach is realized, it can serve the dual purpose of addressing the flaws in traditional methods and revolutionising how we deal with plastic waste.

Tackling Textile Waste

One feature that sets this new depolymerization approach apart is its specificity for PET in textile waste, which is typically a blend of PET and cotton. This has not been easy: conventional recycling approaches do not suit such intricate streams of garbage and we run the risk of losing or diluting precious components.

However, the researchers’ process was able to completely and selectively depolymerize PET present in textile waste, leaving behind DET and EG and materialistically enabling all cotton waste constituent reuse. This is a breakthrough, being that one of the main issues for transitioning into the circular economy has been textile waste.

This approach releases the power of textile waste and promises to be a more universal and effective recycling scheme leading to less environmental damage from other defunct clothing and textile goods. Microporous perfluoro vinyl ether films enable the chemical recycling of PET and cotton with high selectivity, increasing renewable resource utilization while providing new opportunities for upcycling/reuse.

Conclusion

The creation of this advanced chemical recycling process for mixed textile and plastic waste inputs reinforces the progress being made towards a more sustainable world. The solution offered by the researchers could help drive an actual circular economy with a relatively simple, cheap and sustainable method. In the global challenge to tackle plastic, solutions like this can give us hope and drive us to explore new options for waste management and resource recovery.