Researchers have developed an improved electro-Fenton process that utilizes a novel heterogeneous nanocatalyst, Fe-MIL-88B, and simultaneous rotation of the cathode and anode to enhance dye removal from wastewater. This innovative approach outperforms the conventional electro-Fenton process, achieving up to 92.3% dye removal efficiency in just 90 minutes. The study also demonstrates the catalysts’ reusability for up to 6 cycles, making it a cost-effective and environmentally friendly solution. This research holds promise for the treatment of industrial wastewater and the development of advanced wastewater treatment technologies.

Revolutionizing Dye Removal with Innovative Electro-Fenton Process

Dyes are widely used in various industries, but their discharge into the environment can have severe consequences. Conventional wastewater treatment methods often struggle to effectively remove these persistent pollutants. However, a team of researchers has developed an improved electro-Fenton process that combines the power of a heterogeneous nanocatalyst and the innovative design of rotating electrodes to tackle this challenge.

The Power of Heterogeneous Nanocatalysts

The key to the researchers’ approach is the use of a metal-organic framework (MOF) called Fe-MIL-88B as a heterogeneous nanocatalyst. Unlike the traditional homogeneous catalysts used in the electro-Fenton process, Fe-MIL-88B offers several advantages:

– Reusability: The nanocatalyst can be regenerated and reused for up to 6 cycles, reducing operational costs and waste.

– Increased Efficiency: The presence of the nanocatalyst enhances the generation of hydroxyl radicals, which are the primary agents responsible for the degradation of dyes.

– Broader pH Range: The heterogeneous catalyst can function effectively in a wider pH range, unlike homogeneous catalysts that require strict pH control.

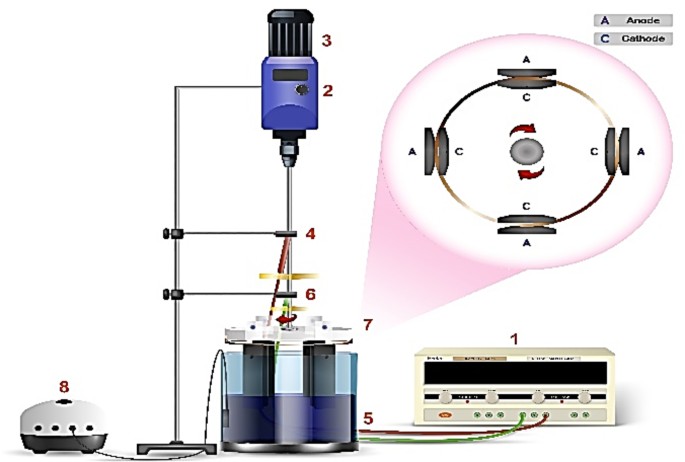

Simultaneous Electrode Rotation for Enhanced Mass Transfer

In addition to the innovative nanocatalyst, the researchers introduced a novel reactor design that features the simultaneous rotation of the cathode and anode. This setup improves mass transfer, ensuring better distribution of the hydrogen peroxide produced during the electro-Fenton process and ultimately enhancing the dye removal efficiency.

Impressive Dye Removal and Mineralization

Under optimized conditions, the improved electro-Fenton process achieved a remarkable 92.3% dye removal efficiency in just 90 minutes, outperforming the conventional electro-Fenton system by 14.5%. Moreover, the process demonstrated significant mineralization, with 77.08% and 63.63% removal of chemical oxygen demand (COD) and total organic carbon (TOC), respectively.

Unlocking the Potential of Wastewater Treatment

The findings of this research highlight the potential of the improved electro-Fenton process for the treatment of industrial wastewater. By leveraging the synergistic effects of the heterogeneous nanocatalyst and the innovative reactor design, the researchers have developed a cost-effective and environmentally friendly solution for the removal of persistent dyes and the conversion of wastewater into less hazardous compounds.

Author credit: This article is based on research by AliAkbar Najafzadeh and Bita Ayati.

For More Related Articles Click Here