In a groundbreaking advancement for sustainable industrial practices, researchers have uncovered 299 alternative substrates across 12 industries that can be used for the production of bacterial cellulose – a versatile biomaterial with applications in food, textiles, and medicine. This systematic review, led by Luis Quijano from the Queensland University of Technology, presents a comprehensive analysis that moves away from the traditional Hestrin-Schramm (HS) media, paving the way for more cost-effective and scalable production. The findings highlight the potential of alternative substrates to not only reduce material loss but also yield higher outputs than the HS media. This work aligns with global sustainability goals, emphasizing the need for interdisciplinary collaboration to address the challenges and unlock the full potential of bacterial cellulose. Cellulose, Biomaterials

Unlocking the Potential of Alternative Substrates

Now, for the first time, an international team of researchers has compiled a systematic review revealing 299 alternative substrates from 12 industries to be used in bacterial cellulose production. It is a significant step towards sustainable industrial practices, as led by the Queensland University of Technology’s Luis Quijano.

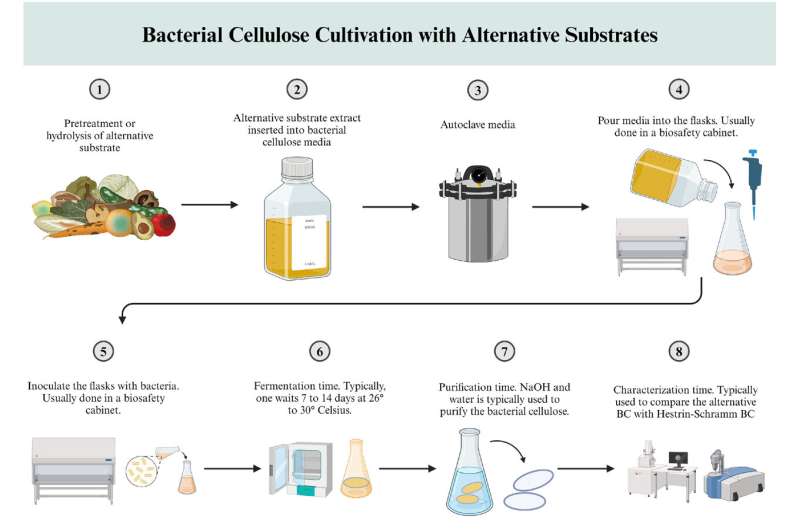

Although the HS media has been traditionally employed to produce bacterial cellulose with great efficiency, it is limited due to expensive and unscalable. Therefore, the researchers, in their most recent article published in the Journal of Bioresources and Bioproducts performed a comprehensive analysis to optimize bacterial cellulose production with minimum loss of materials from a sustainability perspective which leads to more output by using appropriate media and substrate.

Exploring the Versatility of Bacterial Cellulose

Bacterial cellulose is a kind of flexible biomaterial that has shown its great potential in the use of food, textile, or medical industries. In this review, 101 bacterial cellulose-producing strains were systematically compared to provide insights into methodological lapses and the effective utilization of alternative substrates.

This study suggests that these alternative substrates may be not only more economical but also have the potential to outperform traditional HS media. This drives the necessity for Sustainable systems and supply chains, which reduce waste, and leverage energy efficiency through energy conservation. They urge that more studies are needed to make the bio-based polymers processable and affordable, to pave the way for bacterial cellulose as a sustainable and competitive alternative over ordinary plastics.

Towards a Sustainable Future with Bacterial Cellulose

The work with Quijano and his team is a step toward this goal of making bacterial cellulose commercially viable which coincides with the global sustainability targets. In this review, we discuss how bacteria produce biologically-formed cellulose and characterize it in vitro and in vivo; the challenges of bacterial cellulose for industrial applications are highlighted as well, concluding with an emphasis on the power of interdisciplinary interaction to provide combined solutions to these challenges for fully realizing the potential of bacterial cellulose.

After studying other substrates, the investigators have established an efficient and more environmentally friendly way of producing this dynamic biomaterial. According to the researchers, their results highlight how creativity can be engineered through collaboration within key sectors of industry facing some of the toughest environmental and economic pressures. The developments in bacterial cellulose production are exciting progressions to a future of sustainability.