Nature does not work in straight lines and researchers at the Beckman Institute for Advanced Science and Technology make that concept a reality through the development of a groundbreaking experiment End to repeat capable of producing polymer materials containing crystal lattices, which bring resistance with maximum accuracy to create structurally sound polymers applicable to multiple industries.

Mimicking Nature’s Resilience

For many years, scientists and engineers have looked to nature for inspiration and solutions for secrets that have been puzzled about the extraordinary strength and durability of natural structures. For instance, a type of sea sponge that forms in multiple layers combines mineral with softer material to ensure the perfect balance between strength and flexibility.

Researcher Nancy Sottos of the Beckman Institute notes, “Nature has a way of turning normal brittle materials into tough structures really interestingly through architected design. Instead, patterned materials frequently include regions which are part stiff and part soft, enabling them to stretch extensively prior to failure without greatly reducing stiffness.

A Revolutionary Technique

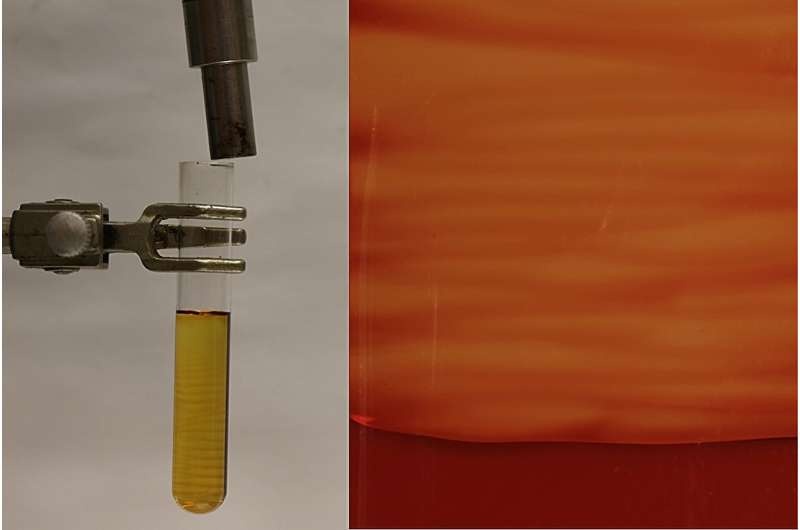

The mechanical engineers at the Beckman Institute have created an original method based on frontal polymerization, in which heat initiates a self-sustaining chemical reaction for polymer processing. Through meticulous management of the chemical reactions, the team recreated the way nature does it, producing structured polymer materials that have both liquid-like or amorphous regions as well as solid-like or crystalline regions.

An interdisciplinary team of scientists were able to achieve this breakthrough by working together, combining their knowledge in materials science, chemistry and aerospace engineering. X-ray scattering experiments aimed to inform how the polymer chains orient themselves in the patterned material came out of the lab of Cecilia Leal, a professor of materials science and engineering, while Philippe Geubelle, an aerospace engineering professor, worked to model and simulate the manufacturing process that can capture localized thermo-chemical instabilities critical for creating such unique heterogeneous materials.

Conclusion

A major advance in the field of materials science has allowed researchers at the Beckman Institute to detect and discover nature’s unbreakable designs. In doing so, they have created a novel method for manufacturing auto-nanostructured polymer materials that are as strong as aircraft-grade aluminium alloys yet six times lighter. It is a testament to nature-inspired innovation and what can be achieved through intersecting state-of-the-art technologies.