Researchers at the University of California, Irvine have made a remarkable breakthrough in understanding the atomic-level mechanisms governing polycrystalline materials, which are widely used in electronic devices, aerospace technologies, automotive applications, and solar energy systems. This discovery provides invaluable insights into optimizing the performance and reliability of these materials, paving the way for advancements in various industries. Polycrystalline materials have long been studied for their unique properties and structural dynamics, and this research offers a transformative understanding of the processes at play.

Unlocking the Atomic-Scale Secrets of Grain Rotation

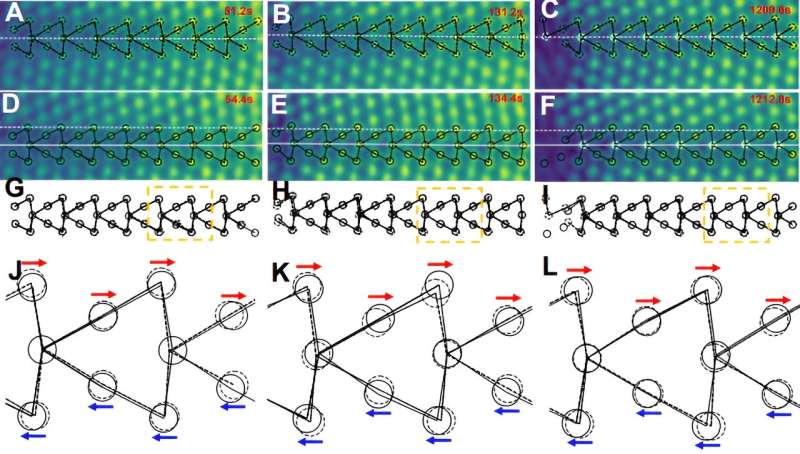

The groundbreaking study, published in the prestigious journal Science, has revealed the atomic-scale mechanisms driving grain rotation in polycrystalline materials. Using state-of-the-art microscopy techniques, including four-dimensional scanning transmission electron microscopy (4D-STEM) and high-angle annular dark-field STEM, the researchers were able to heat samples of platinum nanocrystalline thin films and observe the intricate processes in unprecedented detail.

Previously, scientists had only been able to speculate and theorize about the phenomena occurring at the boundaries of crystalline grains. However, with the employment of these powerful imaging and analysis tools, the researchers have now transitioned from theory to direct, real-time observation of the atomic processes involved. This breakthrough has significantly advanced the understanding of the microstructural evolution in nanocrystalline materials.

The Role of Disconnections in Grain Rotation and Boundary Migration

The study’s key finding is that grain rotation in polycrystalline materials occurs through the propagation of disconnections along the grain boundaries. Disconnections are line defects with both step and dislocation characteristics, and they play a crucial role in the dynamics of these materials.

The researchers discovered that the motion of these disconnections not only drives grain rotation but also influences grain growth and shrinkage. This shear-coupled grain boundary migration, confirmed by STEM observations and supported by atomistic simulations, offers a new perspective on the fundamental mechanisms governing the behavior of nanocrystalline materials. This insight is particularly valuable, as grain boundaries are known to harbor imperfections that can impact the conductivity and efficiency of polycrystalline materials.

Leveraging Machine Learning to Unlock the Complexities

To address the challenge of interpreting the large 4D-STEM datasets, the researchers developed a novel machine learning-based algorithm. This innovative approach allowed them to extract critical information from the data, enabling the team to uncover the statistical correlation between grain rotation and grain growth or shrinkage.

This finding is pivotal, as it not only illuminates the fundamental mechanisms of grain rotation but also provides quantitative and predictive evidence of the atomic-scale processes at play. By understanding how disconnections control grain rotation and grain boundary migration, the researchers have laid the groundwork for new strategies to optimize the microstructures of polycrystalline materials, ultimately leading to enhanced performance and reliability across a wide range of applications.