Learn how catalyst technology can revolutionize the chemicals industry by enabling a future of sustainability & circular economy. In this blog post we will dive into the frontier research that might lead us to a more sustainable and efficient future.

Reshaping the Chemical Landscape

The Importance of Chemistry to the Modern World The chemical industry is a linchpin of global development, generating advancements and offering basic products that make contemporary life possible. But it has imperiled our planet with its unsustainable demand for fossil resources.

Recent statistics maintained by Formulated Polymers note that the chemical industry employs over 20 million people worldwide (excluding refined fossil fuels), accounts for $5.7 trillion of the global economy and contributes to all aspects of human life, hundreds of product applications and is inorganically expanding its product line. However, it also remains the biggest industrial energy user and releases more direct CO2 emissions than any other sector except for power supply and heat. Just in 2022, the sector was responsible for 935 million metric tons of CO2 emissions during primary chemicals production.

In addition to this, operations of the chemical industry have contaminated a lot of water resources and released many toxic substances into the environment which further intensified ecological damage. From here, the researchers claim catalysis could be the solution for an unsustainable model that has lasted decades.

Catalysis: The Key to a Circular Economy

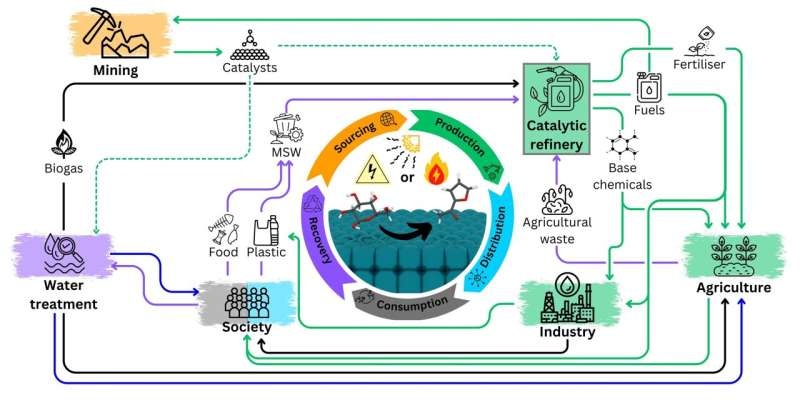

Researchers at Griffith University in collaboration have a suggested new commentary, ‘Catalysis at the Intersection of Sustainable Chemistry and a Circular Economy’, which proposes that catalysis is transformative to overcoming economic waste through its use of sustainable starting materials moving economy from linear (take-refines-use-disposals) into circles where old is converted in making something usable again.

Co-lead author Professor Adam Lee, said: ‘Catalytic processes could help to reduce the need for using up finite fossil fuels and also help to cut CO2 emissions by using waste such as biowaste (from plants and vegetables), Munich Waste, and even plastic rubbish sacks for example as a feedstocks. The new feedstock transition will prevent curtailment of plastic production and also mitigate environmental damage; improve the supply chain resiliency in the industry that suffers from geopolitical or natural disruption.

The co-lead author of the study, Professor Karen Wilson, Director of Griffith’s Center for Catalysis and Clean Energy said catalysis has been instrumental in converting fossil resources into vital fuels and products to date, now it also holds the promise to revolutionise the chemical industries towards a circular economy.

Conclusion

Catalysis holds the key to a more sustainable and circular chemical industry. Through catalytic processes, researchers seek a future where waste is turned into opportunity and greenhouse gases are restricted to solutions leaving the industry less exposed. With that comes the promise this transformational technology can rewrite the chemical script, rewriting the tale on climate impact and driving high paying job growth. In the face of urgent global imperatives such as climate change and resource depletion, the findings from this investigation raise a promising outlook for a cleaner, more sustainable future.