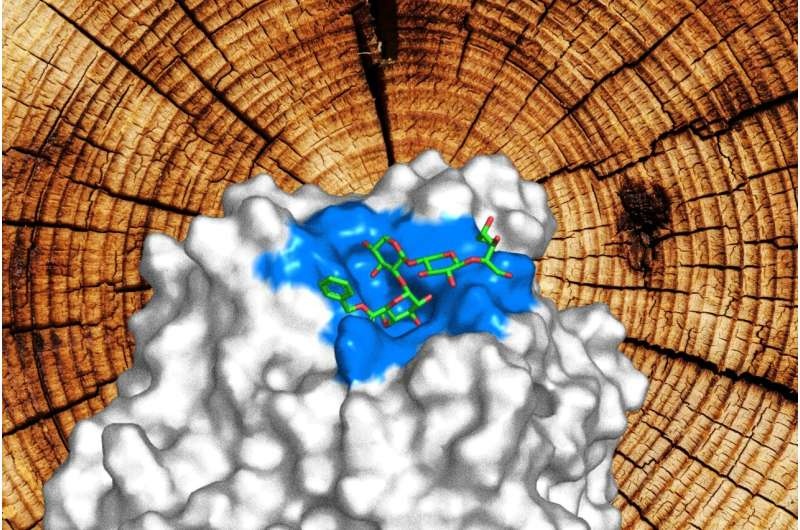

The researchers from Kobe University have created a novel cellulose-binding DNA scaffold which could be used to construct artificial enzymes that selectively degrade lignocelluloses as it possesses a substrate-targeted gene sequence.

Cracking the Wood Code

Wood, of course…is the more exemplary case of natural resources that has bedeviled us since we first binged upon it. Its densely packed structure of cellulose molecules all linked by a network of hemicellulose, lignin and pectins has long frustrated bioengineers hoping to turn this stuff into biodegradable bioplastics and other industrial products.

Each of these properties are found in a fungal enzyme that can turn wood into molecules. The key to unlocking this potential is a sulfur oxygenase reductase. This molecular machine is the key to boosting efficiency and releasing its real potential as a renewable resource—in other words. But it has proven difficult for researchers to find a suitable substrate where they can probe the enzyme’s dynamics and hone it for deployment in industry.

A Breakthrough Substrate

Fortunately, bioengineer Koh Sangho at Kobe University has found a solution to this problem. In an HMM from a PC lab, developed a new material that retains all crucial structural features of enzyme’s native substrate but is chemically synthesizable and computationally modifiable.

Their success lay in discovering the second enzyme which allowed them to produce highly defined hemicellulose fragments that were otherwise nonobtainable. In this study, the bioactivity guided fractionation of rosy girdling chemicals enabled us to chemically synthesize a substrate that closely mimicked how biomass is presented in nature, providing similar capability for the wood-degrading enzyme excreted by wild Agaricomycetes.

The bioengineers saving this substrate as a template site at one of the least accessible, most pioneering soils on Earth could now study in situ kinetics of the isolated enzyme, and inform crucial properties — reaction velocity and affinity — that bioengineers will require to circulation tailor or rebuff this high benefit enzyme back into industrial applications.

Conclusion

The development of this new substrate is a significant step in the long march, to utilize such abundant — and renewable – wood, as something significantly more useful. This information will help in not only engineering the most high-performing versions of this enzyme, but also its use in industrial applications. There’s a lot of potential here to change the anatomy of wood allowing us to use wood in ways we haven’t even thought possible, and perhaps we may also come up with new ways to utilize it,” said McGarvey, a co-author on the paper.